Cookie Machine Factory Biscuit Pattern printing machine

Product Characteristics

With the development of the times, modern people gradually have a better understanding of aesthetics. People are more strict about the food shape. The hollow panda biscuit has a cute shape and a pretty pattern. So Hello Panda biscuit is popular with young people and children. Certainly, Hello Panda has a special producing machine. A cookie pattern printing machine is essential for producing Hollow panda biscuits. Pattern printing machines can make your product more beautiful. However, there are three problems with conventional pattern printing machines. First the speeds of the two rolls are different. But our novel pattern printing machine can have automatic electric synchronization for calibrating two rolls’ speed while making pattern-printed biscuits. Second is difficult to operate. Our pattern machine has a central control system, which provides practical and user-friendly operation function, including an upstream follow-up joint-control function which make machine trial running and daily operation easier for operators and as well as saving operators. Third is hygiene& safety. Our pattern printing drive motor is installed vertically suspended which provides the most effective power output to save energy and is easy to clean and maintain.

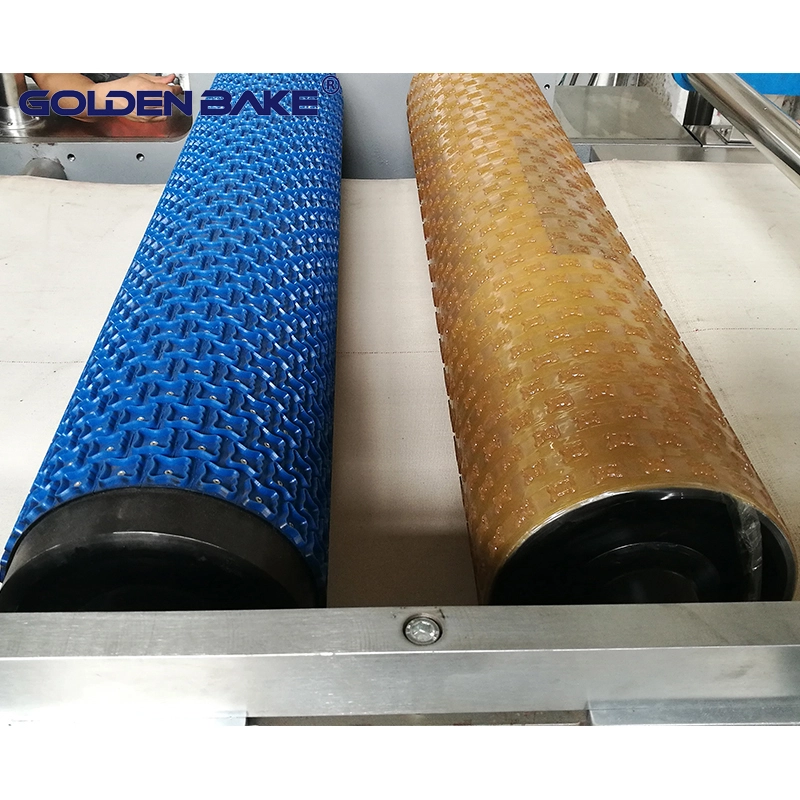

Pattern printing machine for biscuits is installed in the rotary cutter. Pattern printing machines can print patterns that you like. It is used to print the designed patterns on the surface of the biscuit flan( dough sheet) before baking oven, with edible pigment. The surface of these two rollers is made of rubber. One is called a blanking rubber roller and the other is called a steel roller. These two rollers can easily be removed so that it can be easy to clean. Blanking rubber roller can compact press the steel rod to prevent the coating material (Caramel) from infiltrating. Steel roller, which on the surface is engraved with fine netting, and the coating material(caramel)is hidden in the mesh. And it has a PLC system.PLC system can easily control pattern printing machines.

Product Parameters

Cookie pattern printing machine is used to print the designed patterns on the surface of biscuit flan( dough sheet) before baking oven, with edible pigment.

Item | Name | Specification |

| 1 | Dimension | L1400mm*W2150mm*H1300mm |

| 2 | Weight | 1505kg |

| 3 | Power | 3kW+2.2kW+0.4 kW |

| 4 | Wallboard thickness | δ30mm |

| 5 | Type of Rotary Cutter | Double rollers type |

| 6 | Method of rollers' lifting | Pneumatic control with Hand-wheel adjust |

| 7 | Rollers' Synchronization adjustment method | Electricity synchronization |

| 8 | Rollers' diameter | φ230~φ245mm |

| 9 | Biscuit mould' s size | 980mm |

| 10 | Control method | Inverter control motor speed |

| 11 | Conveyor belt | Round canvas belt for cutter, pneumatic correction system. |

| 12 | Pneumatic component brand | SMC |

| 13 | PU belt scraper | 304 Stainless steel |

| 14 | Roller and conveyor motor brand | SEW |

| 15 | Roller and conveyor reducer brand | SEW |

| 16 | Method of operation | Upstream follow-up control function(touch screen+ PLC+ inverter, with memory, breakdown feedback) |

| 17 | Inverter brand | Japan Panasonic |

| 18 | PLC brand | Japan Panasonic |

| 19 | Touch screen brand | Wennview |

| 20 | Electric control brand | Schneider |

| 21 | Out cover material | 304 Stainless steel |

| 22 | Transition support board material | 304 Stainless steel |

| 23 | Bridge board brand | 304 Stainless steel |

| 24 | Support roller treatments | Plated environmental hard chromium |

| 25 | Wall board treatment | PU lacquer |

| 26 | Safety protection | Movement position are installed fixed safety barrier |

Product Characteristics

--Print all kinds of patterns

--Full automation

--Customized

--Quick mould replace

--Pneumatic lifting and handwheel fine-tuning

Product Details

Providing customers with a whole automatic biscuit production line machinery which from material dosing to packing.

Application

CONTACT US

Tel : +86-756-3321360

Fax : +86-756-3321937

Mobile : +86-138-2566-1139

E-mail : biscuitline@126.com

Wechat : +86-138-2566-1139

Whatsapp : +86-138-2566-1139

Add:NO.1, FuTian Road, Nan Xi Industrial Zone Xiang Zhou, Zhuhai, China 519075

BETTER TOUCH BETTER BUSINESS

Contact Sales at GOLDEN BAKE.