Bake Wavy Potato Chip Production Line | Golden Bake

This innovative product meets consumer demand for a "better-for-you" snack without sacrificing the satisfying crunch and premium feel of a ridged chip. The global baked snacks market is a multi-billion dollar industry, projected for significant growth as shoppers actively seek out guilt-free indulgences. By offering a product that is both baked and wavy, you can capture a discerning audience and command premium pricing, ensuring high profitability.

How to start a Baked wavy potato chip business?

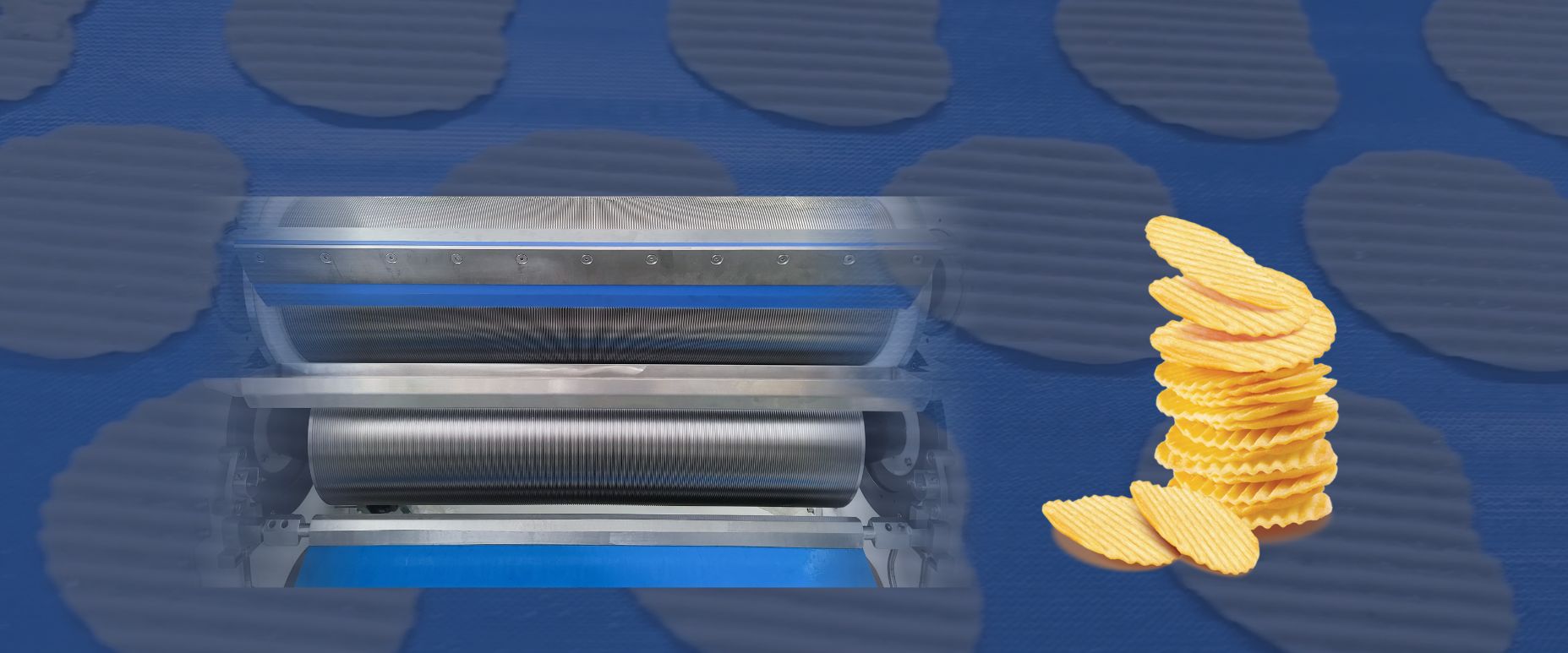

After the dough is ready, it will be transported to the forming process. First, it will pass through a series of rollers to press the dough into a specific thickness, then pass through special corrugated rollers to press it into wavy dough sheets, and then use a roller cutter to cut it into the shape of potato chips. The neatly arranged raw potato chips will pass through the oil sprayer and then enter the tunnel oven for baking. The baking process is the next critical step. The oven is precisely controlled for temperature and humidity, with different zones designed to gradually reduce moisture content and achieve the desired crispness without browning or burning. The "wavy" design of the chips can sometimes require slightly adjusted baking profiles to ensure even cooking throughout the ridges. After baking, the baked potato chips are sprayed with oil, seasoned and cooled. Finally, the baked wavy potato cookies are sorted, metal-detected, and packed into bags or boxes in predetermined quantities for distribution. Every step of the process is strictly monitored to ensure the consistency and quality of each batch of products.

For more products related question, Welcome to inquiry us.

If you have any questions about our products or services, feel free to reach out to customer service team.

Baked wavy pOTATO CHIP machine

2) LCD touch panel, PLC control, computer memory function, drive part servo motor.

3) Working width reachs Max.1200mm

4) The shell of the machine is made of stainless steel and aluminum, which is easy to clean.

5) Through the optimization of oven design details such as combustion efficiency, insulation and exhaust of the oven, our oven energy consumption is lower

6) The gauge rolls and corrugated roller are made of chilled alloy, which meets food safety and durability. Especially for corrugated rollers, ensure that there is no peeling, no slag, no health risks.

7) Better taste of the product (from customer sharing)

8) The combustion chamber for the 3 convection zone adopt 310S stainless steel imported from Sweden with temperature resistance up to 1200℃

|

Hourly output of naked biscuits (excluding packaging film and plastic tray): |

Actual output 600kg per hour normally at baking time 4min30sec Max.about 650kg per hour at 4min10sec |

|

Main motor reducer |

SEW |

|

Pneumatic parts |

AIRTAC |

|

Main bearing |

SKF |

|

Servo motor |

Siemens |

|

Circulating fan |

Dongrun fan |

|

Pipe ribbon burners for DGF (zone 1 & zone 2) |

Made by D-One, with imported 316L stainless steel ribbon net (900℃ resistant) |

|

Combustion champers for DFC (zone 3,4,5) |

Made by D-One, with imported 310S stainless steel.(1200℃ resistant) |

|

Big burners for DFC |

Weishaupt, Germany |

|

Oven steel band |

Sandvik /sweden |

|

Conveyor PU belt |

Shanghai yongli |

|

PLC |

Siemens |

|

Touch screen |

Siemens |

|

Low-voltage apparatus |

Siemens |

|

Inverter |

Danfoss |

|

Gas combustion related accessories |

RapidFlame, UK |

|

Proximity switch |

AUTONICS |

|

Photoelectric eye |

SICK |

|

Limit switch |

Tend |

|

Power supply unit |

WEAN WELL + Siemens |

|

Dough sheet thickness detector |

German NOVO displacement sensor |

|

Control cabinet |

Combe |

|

Fuse |

Chint |

|

Temperature probe |

Zhaoyi |

|

Thermocouple |

Zhaoyi |

|

Casters and hand wheels |

Italy ELESA + GANTER |

FAQ

GET IN TOUCH

Our comprehensive after-sales service program is available throughout our lines’ entire life cycle. Please feel free to contact us if you need any further information on the industrial biscuit machinery. We will offer you customized solutions for your demands.

CONTACT US

Tel : +86-756-3321360

Fax : +86-756-3321937

Mobile : +86-138-2566-1139

E-mail : biscuitline@126.com

Wechat : +86-138-2566-1139

Whatsapp : +86-138-2566-1139

Add:NO.1, FuTian Road, Nan Xi Industrial Zone Xiang Zhou, Zhuhai, China 519075

BETTER TOUCH BETTER BUSINESS

Contact Sales at GOLDEN BAKE.