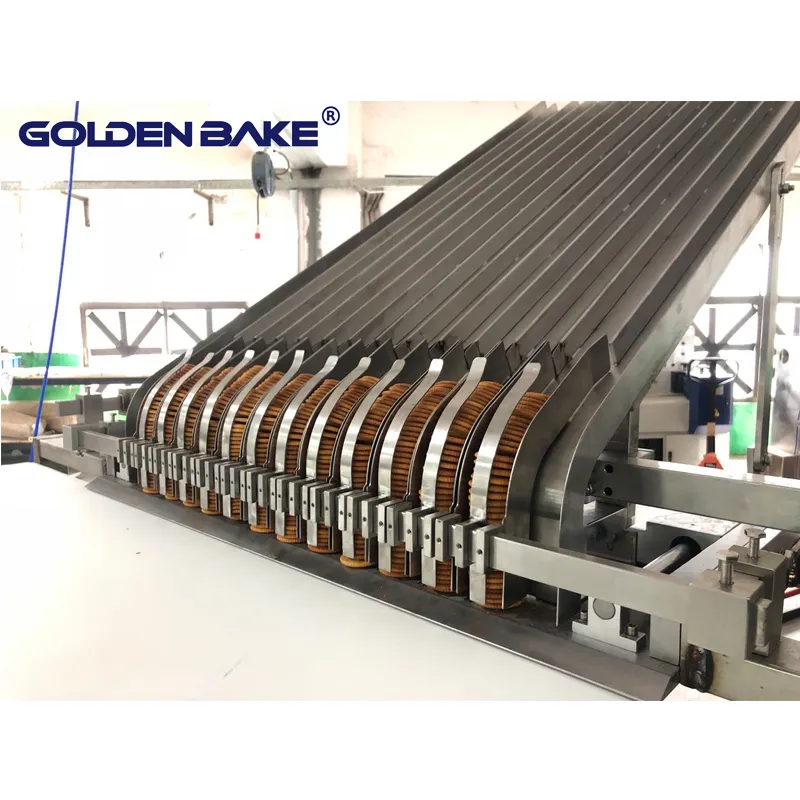

Golden Bake top quality cooling tunnel vendor for biscuit cream filling

Place of Origin:

China

Payment:

L/C, T/T

MOQ:

≥1

Model:

No

Brand:

Golden Bake

cooling tunnel

description

Under the supervision of professional quality inspectors, the products are inspected at every stage of production to ensure the superior quality of the products. This product has the ability to provide repeated production accuracy

cooling tunnel

SPECIFICATIONS

| Model | No |

|---|---|

| MOQ | ≥1 |

| Payment | L/C, T/T |

| Place of Origin | China |

| Brand | Golden Bake |

| Material | SUS 304 |

| Certification | CE |

| Delivery Time | 30days |

| Start Port | Any port of china |

This product is highly resistant to strong chemicals. This product is able to provide satisfying biscuit shapes. Extreme temperature variations will not change the property of this product.

Suggested Videos

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

CONTACT US

Tel : +86-756-3321360

Fax : +86-756-3321937

Mobile : +86-138-2566-1139

E-mail : biscuitline@126.com

Wechat : +86-138-2566-1139

Whatsapp : +86-138-2566-1139

Add:NO.1, FuTian Road, Nan Xi Industrial Zone Xiang Zhou, Zhuhai, China 519075

BETTER TOUCH BETTER BUSINESS

Contact Sales at GOLDEN BAKE.