400 Horizontal Dough Mixer for Biscuit Line

Product characteristics

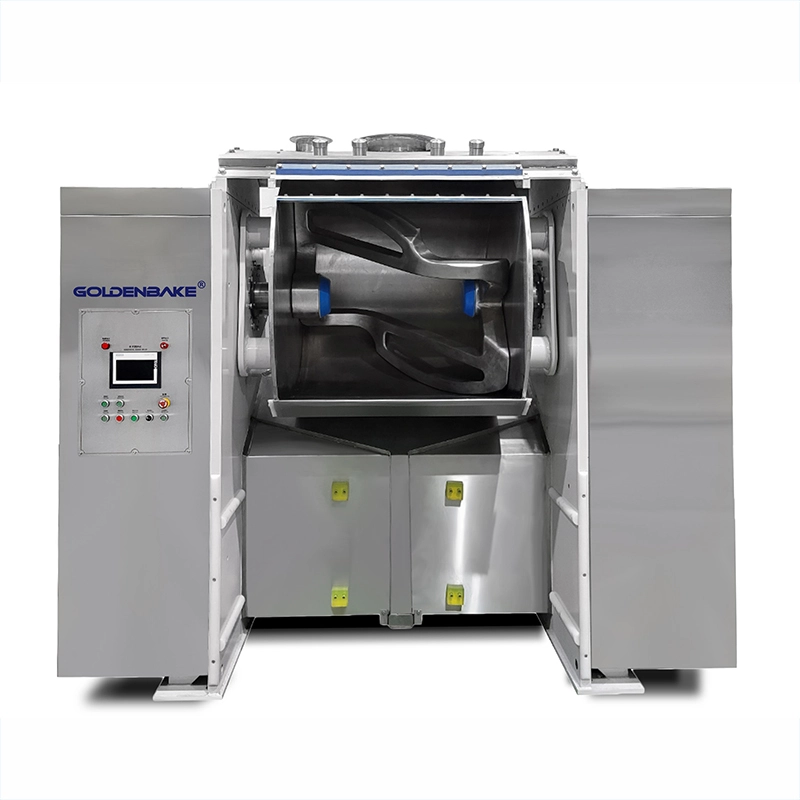

The 400 horizontal dough mixer consists of two main parts, the control cabinet and the mixing part. The control cabinet equipped with PLC touch screen to control the frequency of motor speed with soft start device for stepless speed change, to bring the dough fully mixing. It will improve the mixing quality. The mixing part includes power part and stirring paddle. The dough tub of a horizontal mixer cannot be moved, it can only be tilted. So that so the best place to install a horizontal mixer is on either side of a dough kibbler or a dough conveyer. Our horizontal mixer tilts at 91°to ensure the dough can pour directly into the dough kibbler. Since the barrel cannot be moved in a horizontal dough mixer, it is not suitable for use with hard dough that needs to be fermented. The whole machine body is made of all stainless steel and food-grade material.

Mixing is critical to developing the soft extensible dough. A mixing action that kneads the dough without too much tearing and extruding is ideal.

Product parameters

Providing customers with a whole automatic biscuit production line machinery which from material dosing to packing.

Item | Name | Specification |

1 | Motor power | 55kW+2.2kW |

2 | capacity | 400kg dough/time, 300kg flour/time |

3 | Mixer type | P∽ type |

4 | Mixing speed | 27-56r/min |

5 | Control method | Controlled by Siemens PLC and touch screen, with recipe control program, real-time monitoring of stirring current, elapsed stirring time, and remaining stirring time |

6 | Speed control method | Stirring paddle frequency conversion speed regulation, the maximum speed is 60 rpm |

7 | Motor brand | SEW |

8 | Tilting form | inching |

9 | Reducer brand | SEW |

10 | Barrel material | 304Stainless steel, the effective volume is 750L, and it adopts two-layer design inside and outside, with a water-circulating insulation layer in the middle, which has the function of ice water access and control |

11 | Cover treatment | Stainless steel |

12 | Wallboard treatment | The multi-layer seal design is adopted between the shaft of the stirring paddle and the mixing barrel to effectively prevent leakage, and the seal is separated from the bearing to avoid the contamination of the dough by lubricating grease after the seal is damaged |

13 | Tilting angle | Customized:91°~120° |

| 14 | Dough barrel | 304 stainless steel is welded and polished. Each mixer is randomly distributed with 1 stainless steel dough tank. The dough tank uses 4 Italian ELESA+GANTER casters, two of which are universal wheels and two are fixed wheels. |

Horizontal dough mixer characteristics

-- Equipped with the button touch control to convenient for workers when they get some flour or oil on their hands.

-- Easy to place and move in factory with small size.

-- Easy to pour flour and other material with low-height.

-- Can be directly connected with silo system to achieve the online mixing effect.

Product Details

Providing customers with a whole automatic biscuit production line machinery which from material dosing to packing.

① Connect with the Automatic Silo and dosing system

All in one, mixing including flour,sugar,water,oil and other material

② Stirring paddles are made of duplex stainless steel after precision casting and polished

Application

CONTACT US

Tel : +86-756-3321360

Fax : +86-756-3321937

Mobile : +86-138-2566-1139

E-mail : biscuitline@126.com

Wechat : +86-138-2566-1139

Whatsapp : +86-138-2566-1139

Add:NO.1, FuTian Road, Nan Xi Industrial Zone Xiang Zhou, Zhuhai, China 519075

BETTER TOUCH BETTER BUSINESS

Contact Sales at GOLDEN BAKE.