Product details of the bakery tunnel oven

Quick Detail

Golden Bake bakery tunnel oven is creatively designed to help customers break into the fast-growing market. The quality of the product is recognized by the international specification. Various in function and wide in application, the bakery tunnel oven can be used in many industries and fields. Since the establishment of the Golden Bake Group, its sales network has spread all over the country.

Product Information

Compared with ordinary products, Golden Bake Biscuit Production Line's bakery tunnel oven has the following advantages in details

Product Characteristics

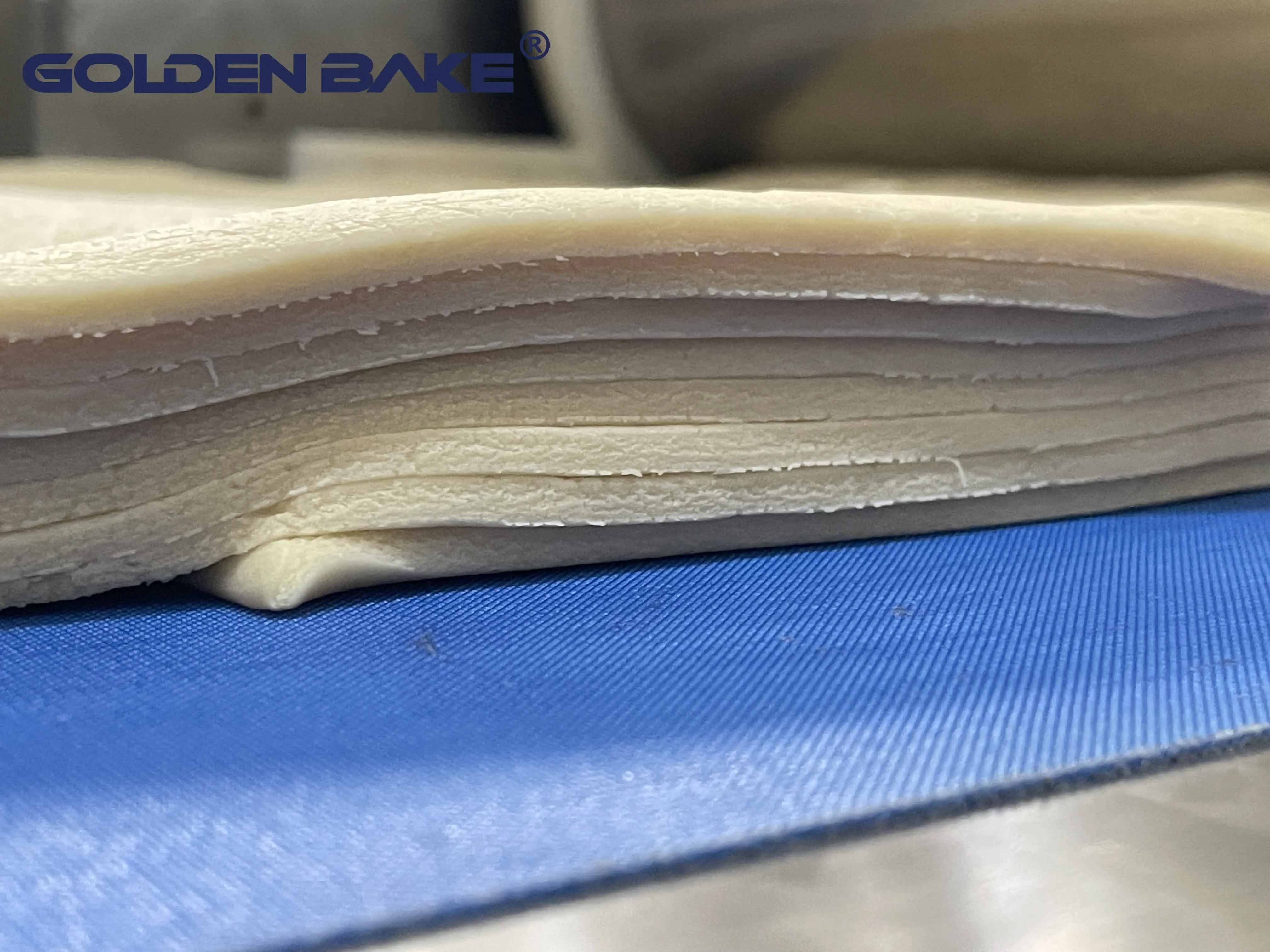

The cut sheet laminator is placed in the front of the forming machine and behind the dough cutter conveyor. It is used to laminate dough sheets by cutting the dough sheet into slices and sending them to three-gauge rollers. Cut sheet laminator is mainly used for pre-made dough sheet, laminating, and sprinkling powder in the preparation of hard biscuits especially crackers, (soda or cream) as it overlaps layers of dough sheets which as a consequence give the flaky appearance and texture to the final products. What’s more, it can also balance the gluten inside the dough sheet. It is especially necessary for producing most of the hard biscuits like soda biscuits, crackers and so on. Cut sheet laminator lays each dough sheet onto the previous one. Thus overlapped, the dough is received by a lower discharge conveyor and then transferred to the next set of gauge rollers to be gauged to the final thickness before entering the rolling cutter.Our cut sheet laminator is equipped with Touch screen control, PLC control system, and variable frequency speed regulating motor, it can be operated separately or together, the automation is fine. As a result, it is easy and convenient to operate. Besides it’s designed with 15 motors, 8 inverters and 4 servo motors to get accurate size and even thickness dough sheet. The number of layers of cut sheets,width of dough sheets,the thickness of the dough sheet and continuous laminating are adjustable. The dough sheet thickness varies from 3 to 15mm and the width is is about 550mm/810mm. The layers of laminated dough sheet is 4—12 . All technology and advanced parts applied in our lamiator have contributed to better muti-layered texture of biscuits and improving the quality and grade, especially for soda cracker and cream cracker.

Cut sheet laminator

Providing customers with a whole automatic biscuit production line machinery which from material dosing to packing.

Item | Name | Specification |

| 1. | Dimension | L2700mm*W2400mm*H2780mm |

| 2. | Weight | 8500kg |

| 3. | Power | 16kW |

| 4. | rooved rolls | φ400mm×2 pieces and φ230mm×1 piece |

| 5. | Gauge rolls | φ230mm×4 pieces |

| 6. | Material of gauge rolls | Chilled alloy |

| 7. | Material of roller edger | PP |

| 8. | Material of conveyor | PU belt with conducting bar |

| 9. | PU belt scraper | PP |

| 10. | Laminating layers | From 4 to 12 layers (adjustable) |

| 11. | Width of cut layer | 1450mm~1550mm(adjustable) |

| 12. | Thickness of dough sheet | 2~15mm (adjustable) |

| 13. | Control style | Human-computer interface, motor speed control by inverter, single machine control, upstream follow-up control. |

| 14. | Control style of sheet cutting | Sanyo servo motor. |

| 15. | Motor brand | SEW |

| 16. | Reducer motor brand | SEW |

| 17. | Gauge roll bearing | NSK |

| 18. | Operation method | Touch screen |

| 19. | Inverter brand | Japan Panasonic |

| 20. | PLC brand | Japan Panasonic |

| 21. | Touch screen brand | wennview |

| 22. | Control electric brand | Schneider |

| 23. | Material of outer cover | 304 Stainless steel |

| 24. | Transition support board material | 304 Stainless steel |

25. | Hopper material | 304 Stainless steel |

| 26. | Support roller treatments | Plated environmental hard chromium |

| 27. | Wall board treatment | PU lacquer |

Shortening powder duster machine (inside laminator)

Item | Name | Specification |

| 1. | Dimension | L930mm*W1320mm*H470mm |

| 2. | Weight | 125kg |

| 3. | Total power | 0.37kW+0.37kW |

| 4. | Speed control method | Motor speed controlled by inverter |

| 5. | Inverter brand | Japan Panasonic |

| 6. | Conveyor material | 304 Stainless steel mesh belt |

| 7. | Cover,hopper and wall board | 304stainless steel |

| 8. | Sprinkling method | Vibrator roller |

| 9. | Motor brand | Taiwan Yuxin (GH) |

Product Characteristics

-Design with 15 motors, 8 inverters and 4 servo motors to get accurate size and even thickness dough sheet-Can make 4-12 layer-Mesh belt vibration dusting evenly-Independent design, easy to move, clean and maintai

Product Details

Providing customers with a whole automatic biscuit production line machinery which from material dosing to packing.

① Conveying the hard dough to the cut sheet laminator from the hard dough cutting machine.

② Equipped with the shortening powder duster machine to make more layer texture.

Application

Company Advantages

Golden Bake Group is a modern company located in zhu hai. And the main product is biscuit machine,cookie machine,biscuit production line. Golden Bake Biscuit Production Line adheres to the business philosophy which is to share the joy and worry with customers and seek common development with society. We also promote our enterprise spirit of 'integrity, innovation and win-win'. Based on honesty, we emphasize development and innovation and hope to cooperate with like-minded people. Together we can achieve a win-win situation and create brilliance. With high-quality technology research team and production team, independently develops and research the products by using advanced technology and methods. Golden Bake Biscuit Production Line has an excellent team consisting of R&D, production, operation and management. According to actual needs of different customers, we could provide customers with practical solutions.

We have many years of experience in production and sales. And if you are interested in our products, feel free to contact us.

CONTACT US

Tel : +86-756-3321360

Fax : +86-756-3321937

Mobile : +86-138-2566-1139

E-mail : biscuitline@126.com

Wechat : +86-138-2566-1139

Whatsapp : +86-138-2566-1139

Add:NO.1, FuTian Road, Nan Xi Industrial Zone Xiang Zhou, Zhuhai, China 519075

BETTER TOUCH BETTER BUSINESS

Contact Sales at GOLDEN BAKE.