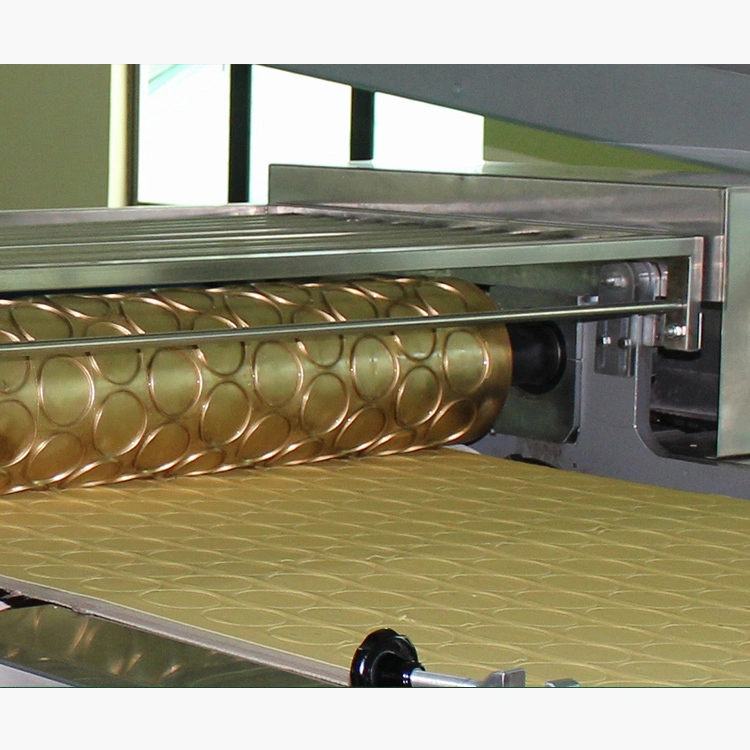

Rotary cutting machine--- cut the dough sheet in special shape

Product Specifications

|

Power |

6.5kw |

Weight |

2300 KG |

|

Material |

304 Stainless steel |

Size |

2650mm*1770mm*1400mm |

|

Brand |

GOLDEN BAKE |

Motor |

SEW |

|

Double Die Rollers |

1. Printing Roller 2. Cutting Roller |

Die Roller Bearings |

NSK |

|

Mixing Barrel |

Water Jacketed |

Operation panel |

Siemens PLC Touch Screen |

|

Conveyor Belt |

Seamless canvas belt |

Frame |

Steel plate CNC processed surface paint |

|

MOQ |

≥1 Set |

Servo Motor |

Siemens |

Product Description

Our rotary cutter is equipped with pneumatic lifting and fine-tuning of the hand wheel. The Central Control System provides practical and user-friendly operation functions, including upstream follow-up joint-control function, which makes machine trial running and daily operation easier for operators and as well as saving operators. Its automatic electric synchronization is for calibrating two rolls’ speed while making pattern-printed biscuits and the menu memory and call-out function make it easy to make the same product next time. The Roller’s gap distance adjustment adopts electricity motor-driven screw lifting, making it longer working life rather than an eccentric wheel and easier operation for workers. The Drive motor is installed vertically suspended which provides the most effective power output to save energy and is easy to clean and maintenance. What’s more, machines can be either controlled flexibly via touch screen or by buttons. Last but not least, its high speed and low noise can meet the requirements for maximum production capacity.

PRODUCT ADVANTAGE

rotary cutter

--Safety protection functions

--Pneumatic lifting and handwheel fine-tuning.

--Automatic electric synchronization for calibrating the two rolls’ speed while making a pattern printed biscuit.

--Central Control System provides practical and user-friendly operation functions, including upstream follow-up joint-control function, which makes machine trial running and daily operation easier for operators and as well as saving operators.

--Menu memory and call out function, easy for next time making the same product.

--Machines can be controlled flexibly via touch screen or by buttons.

--Roller’s gap distance adjustment adopts electric motor-driven screw lifting, making it longer working life than eccentric wheel and easier operation for workers.

--Drive motor is installed vertically suspended, which provides the most effective power output to save energy and is easy for cleaning and maintenance.

PRODUCT DETAILS

Product application

Suitable hard dough biscuit/cracker production lines

Frequently Asked Questions

CONTACT US

Tel : +86-756-3321360

Fax : +86-756-3321937

Mobile : +86-138-2566-1139

E-mail : biscuitline@126.com

Wechat : +86-138-2566-1139

Whatsapp : +86-138-2566-1139

Add:NO.1, FuTian Road, Nan Xi Industrial Zone Xiang Zhou, Zhuhai, China 519075

BETTER TOUCH BETTER BUSINESS

Contact Sales at GOLDEN BAKE.