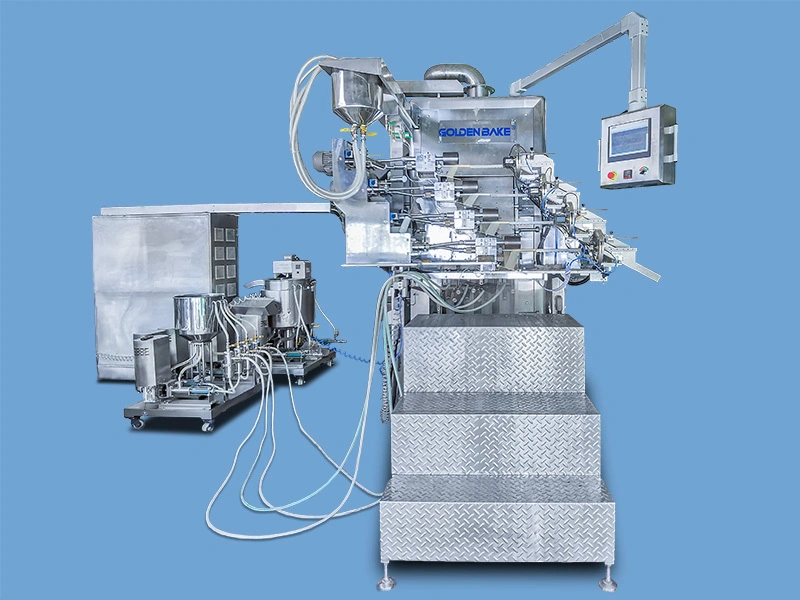

Automatic egg roll machine wafer stick making machine biscuit production line

Product Description

As we all know, it is very tedious and complex to make common handmade wafer sticks. Need to mix the flour, egg liquid, and white sugar into a batter, add the butter to the flakes, smear the butter, and then roll into a roll shape. Making egg rolls by hand requires a lot of time and labor, and cannot work all day. Only suitable for family workshops, not for mass production.

Different from the mechanized production of wafer sticks. An automatic wafer stick production line is adopted for the mechanized production of egg rolls, which can be directly connected from the mixing steps to the packaging steps.

1. Mixing egg, flour and water into a paste. The mixed paste is injected into the baking roller by the filling equipment and baked into a ribbon dough sheet;

2. Use a crimping device to curl the dough sheet into an egg roll without using water for bonding;

3. Cutting the egg rolls evenly according to the length set by the customers;

4. Cool, cool and pack the wafer stick.

Product Parameters

Providing customers with a whole automatic biscuit production line wafer stick machine which from material dosing to packing.

No. | Item | Specification |

1 | Load-carrying Capacity | 800kg/m2 |

2 | Main Machine Dimension | 2480×1800×2300 mm |

3 | Main Machine Weight | 4300kg |

4 | Batter / Cream Supply Machine Dimension | 800×800×800 mm |

5 | Batter / Cream Supply Machine Weight | 150kg |

6 | Cooling Conveyor Dimension | 4000×350×950 mm |

7 | Cooling Conveyor Weight | 160kg |

8 | Capacity | φ9mm inject tube, length: 100mm, cream injection:35%, 50kg/h(about 100 pieces/min), roll’s length ranges from 60~220mm(adjustable) |

9 | Gas supply | Customer provide gasification equipment with reducing valve (20kg/h) for LPG or natural gas (Pressure: 2.8Kpa) |

10 | Air Pressure supply | Capacity: 0.3-0.5 m3 Pressure: 0.2-0.5Mpa |

11 | Power | About 6.6kw |

12 | Gas type | LPG / natural gas |

13 | Consumption of gas | LPG 4.2~5.5kg/h, natural gas 7.5~9.5 m3/h |

14 | Baking wheel material | Heat-resistant cast iron alloy |

15 | Diameter of baking wheel | φ2000mm |

16 | Amount of batter forming | Two lines(double colors per line) |

17 | Mode of bottom heating | Direct fire heating |

18 | Mode of top heating | Infrared burner from Japan |

19 | Mode of temperature control | Manually, temperature display |

20 | Mode of ignition | Ignited by ignition control module automatically |

21 | Mode of monitor of fire | Monitored by ignition control module automatically |

22 | Mode of safety | Cut the burner and alarm automatically by ignition control module |

23 | Forming scroll material | Die steel |

24 | Forming scroll material | A3 steel |

25 | Mode of cut | Pneumatic |

26 | Mode of length detecting | Photoelectric switch |

27 | Central batter conveying & control mode | Stainless steel rotor pump, frequency conversion & PLC touch screen control |

28 | Side batter conveying& control mode | Gear rotary pump, frequency conversion & PLC touch screen control |

29 | Inside core conveying & control mode | Stainless steel rotor pump, frequency conversion & PLC touch screen control |

30 | Bigger roll speed adjustment | Frequency conversion &PLC touch screen control |

31 | Forming speed adjustment | Frequency conversion &PLC touch screen control |

32 | Batter conveying speed adjustment | Frequency conversion &PLC touch screen control |

33 | Conveying belt speed adjustment | Frequency conversion &PLC touch screen control |

34 | Material barrel heating | Electrical heating & PLC touch screen control |

35 | Material barrel mixing | AC Constant speed & PLC touch screen control |

36 | Material of material barrel | 304 interlayer stainless steel |

37 | Bigger roll reducer brand | Changzhou Jiangnan(China famous brand) |

38 | Forming machine bearing brand | Japan NSK |

39 | Stainless steel rotor pump brand | JONHEN |

40 | Forming machine motor | Taiwan Yusin Gearmotor |

41 | Inverter brand | Japan Panasonic |

42 | PLC brand | Japan Panasonic |

43 | Photoelectric switch | Japan Yamatake |

44 | Ignition magnetic valve | Taiwan |

45 | Ignition controller | Taiwan Kingpin |

46 | Control electrical component | France Schneider |

47 | Main forming machine cover | 304 stainless steel |

48 | Conveyor cover | 304 stainless steel |

Product Characteristics

Details on wafer stick machine

Our egg roll machine/wafer stick machine costs only one labor. Saving labor costs and greatly increasing the output of wafer sticks. Fully automated production of egg rolls have smooth surface, smooth incision and the finished product length remains consistent. No pressure to product wafer stick in 24 hours. In addition, the machine can be configured according to customer requirements to do double color egg roll or the center filled with cream. Or optional flattening mechanism for flattening egg rolls or pillow egg rolls.

Full set of wafer stick automatic production line including: Wafer stick machine and Packing conveyor.

Product Details

Providing customers with a whole automatic biscuit production line egg roll machine which from material dosing to packing.

Full set of automatic Wafer Stick/Egg roll machine including: Wafer stick forming system and Baking oven, Batter and cream supply machine, Cooling conveyor, Packing machine.

Application of Wafer Stick Machine

Frequently Asked Questions

CONTACT US

Tel : +86-756-3321360

Fax : +86-756-3321937

Mobile : +86-138-2566-1139

E-mail : biscuitline@126.com

Wechat : +86-138-2566-1139

Whatsapp : +86-138-2566-1139

Add:NO.1, FuTian Road, Nan Xi Industrial Zone Xiang Zhou, Zhuhai, China 519075

BETTER TOUCH BETTER BUSINESS

Contact Sales at GOLDEN BAKE.